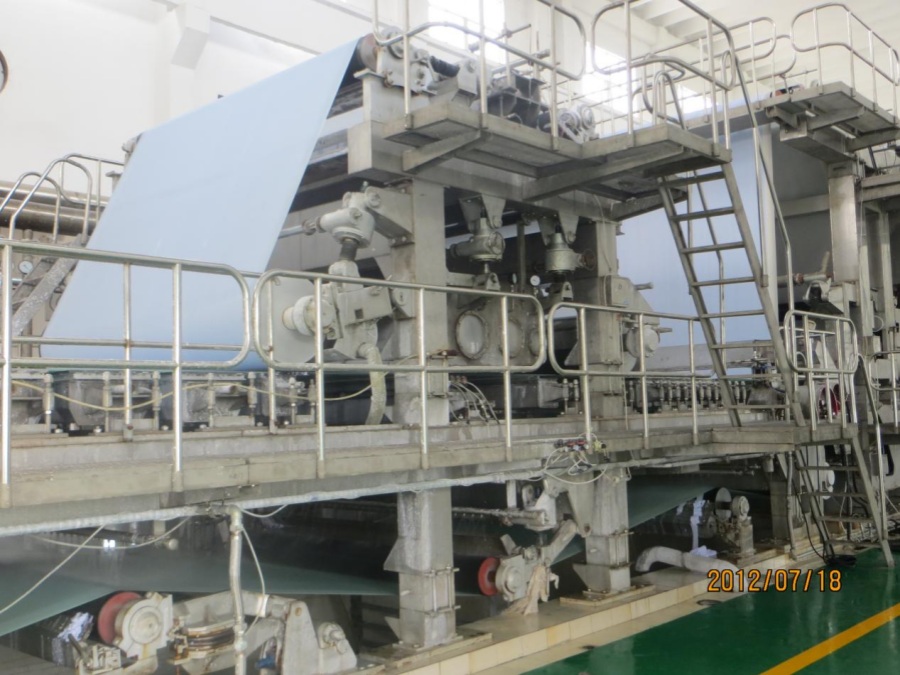

Upgrading Paper Machine

In today's highly competitive paper industry, companies face ever-changing market demands and increasingly stringent environmental standards. To maintain competitiveness, many paper mills are considering upgrading and retrofitting their existing paper machines. This article will explore the necessity, advantages, and implementation plans for paper machine upgrades.

Why Choose Upgrading and Rebuilding?

1. Increase Production Efficiency

With advancements in technology, modern paper machines have significantly improved production efficiency. By upgrading and retrofitting, companies can leverage new technologies and equipment to shorten production cycles and increase output, thereby meeting market demand for paper products.

2. Improve Product Quality

Older equipment may not meet current quality standards. By introducing advanced control systems and detection technologies, upgraded paper machines can better control the thickness, smoothness, and strength of the paper, ensuring that product quality meets or exceeds industry standards.

3. Reduce Energy Consumption and Environmental Impact

The latest generation of paper machines has shown significant improvements in energy efficiency. Upgrading and retrofitting can help companies lower energy consumption and reduce waste emissions during production, complying with environmental regulations and enhancing the company's image of social responsibility.

Key Components of Upgrading and Retrofitting

1. Automated Control Systems

Introducing advanced automated control systems allows for real-time monitoring and adjustment of the production process, improving stability and consistency.

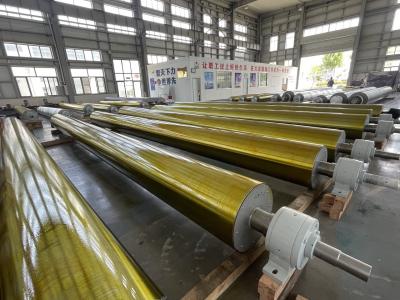

2. Tension Control Technology

Precise tension control technology ensures the stability of the paper during production, reducing defects and increasing yield.

3. Cutting and Rewinding Mechanisms

Upgrading cutting and rewinding mechanisms enhances cutting precision and rewinding efficiency, ensuring that every roll of paper meets quality and specification standards.

4. Equipment Maintenance and Training

During the retrofitting process, providing equipment maintenance and operational training ensures that employees can proficiently operate the new equipment, thereby improving production efficiency.

Implementation Plan

1. Assess Existing Equipment

Before upgrading and retrofitting, a comprehensive assessment of existing equipment is necessary to identify performance bottlenecks and retrofitting potential.

2. Develop a Retrofitting Plan

Based on the assessment results, a detailed retrofitting plan should be developed, including technical solutions, budget, and timeline.

3. Implement the Retrofitting

Gradually implement the retrofitting plan while ensuring production safety, minimizing disruptions to ongoing operations.

4. Post-Retrofit Support and Maintenance

After the retrofitting is complete, provide ongoing technical support and equipment maintenance to ensure long-term stable operation.