New Challenge and New Break Through

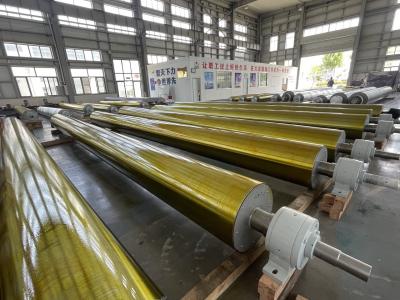

Series 1: German company-Inspired Traction & Winding Rolls for 700 m/min, 10.4 m BOPP Lines

This series has been developed for BOPP production lines with a web speed of 700 m/min and a width of 10.4 meters, incorporating advanced design concepts from the latest Germanic machinery. Our corona roll features an optimized diameter of 828 mm, ensuring exceptional film handling stability under high-speed operation. The accompanying corona nip roll utilizes full carbon fiber composite construction, reducing weight by over 40% compared to conventional steel rolls. This significant weight reduction minimizes rotational inertia and energy consumption, making these rolls ideal for continuous high-speed production. The series represents a complete upgrade solution for modern BOPP lines seeking to enhance both output efficiency and energy performance.

Series 2: French company-Oriented Carbon Fiber Roll Systems for 10.6 m Wide Lines

Specifically engineered for French company's state-of-the-art 10.6-meter wide production lines, this series fully embraces carbon fiber technology. The flagship carbon fiber cooling roll features an innovative triple-layer construction: a carbon fiber inner tube for structural integrity, a carbon fiber outer tube for superior thermal conductivity, and a thin stainless steel sleeve (available with chrome plating option) that provides outstanding wear and corrosion resistance. This series also includes matching corona rolls, nip rolls, and guide rolls, offering a unified carbon fiber solution for complete production line modernization. The reduced weight and enhanced thermal properties contribute to higher line speeds and improved product quality.