Paper Machine Guide Roll: Key Paper Making Equipment

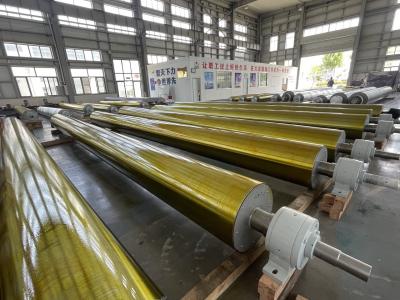

Paper machine guide roll: key paper making equipment

In the process of paper production, there are many key equipment and components, among which the paper machine guide roll is one of them.The paper machine guide roll is an important device used to control the direction and speed of paper movement, and it plays a vital role in the process of paper production.This article will provide a detailed introduction to the structure, function, and application of the paper machine guide roll in paper production.

I. Structure of paper machine guide roll

The guide rollers of the paper machine are mainly composed of a roller body, bearings, seals, etc. The roller body is the main part of the guide roller, usually made of steel, with a special surface treatment, which has high wear resistance and corrosion resistance.The bearings are the core components of the guide roller, which bear the gravity of the roller body and the pressure generated by the movement of the paper, ensuring the normal operation of the guide roller.The seals are mainly used to prevent the friction between the paper and the roller body from causing damage to the paper, and also play a role in dustproof and waterproof.

II. Function of paper machine guide roll

1. Control the direction of paper movement: The guide rollers of the paper machine change the direction of paper movement to enable the paper to follow a set path, thereby meeting the production requirements of the paper.

2. Adjusting the paper movement speed: The paper machine guide rollers can effectively control the paper movement speed by changing the rotational speed of the roller body, meeting the requirements of different paper production.

3. Stabilizing paper tension: During the movement of the paper on the paper machine guide rollers, the tension of the paper can be adjusted by changing the position of the roller body to ensure the stability of the paper during production.

4. Protecting the surface quality of paper: The seals on the guide rollers of the paper machine can reduce the friction between the paper and the roller body, avoiding paper damage caused by friction and ensuring the surface quality of the paper.

Application of paper machine guide rollers in paper production

The guide rollers of paper machines play a very important role in paper production, as they directly affect the quality, output, and production efficiency of the paper.Here are some applications of paper machine guide rollers in paper production:

1. Paper sheet forming: During the paper sheet forming process, the paper machine guide rollers control the direction and speed of the paper sheet movement, enabling the paper sheet to be formed according to the set shape and size, thus achieving precise paper sheet forming.

2. Paper traction: During the paper traction process, the paper machine guide roll changes the direction of the paper sheet movement, pulling the paper sheet from the forming section to the press section to achieve continuous production of paper sheets.

3. Paper tension control: During the paper traction process, the paper machine guide rollers adjust the tension of the paper to ensure the stability of the paper during production and improve the quality of the paper.

4. Paper drying: During the drying process of paper, the guide rollers of the paper machine control the speed of the paper movement, allowing the paper to be evenly heated in the drying section, improving the drying effect of the paper.