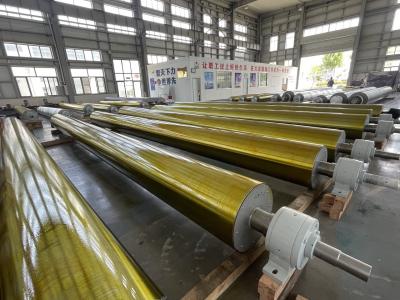

Trial run of suction roll

Trial run of suction couch roll

After the installation of suction couch roll and fully inspected, it can do trial run without loading from the low-speed to high-speed under the condition of meeting the installation quality requirements, connecting water, gas and compressed air and ensuring the supply conditions. It’s strictly prohibited running without water. Before running, the suction roll must be cleaned, inspected and oiled. It should be inspected whether each moving part is flexible. Separatly test run to see whether the operation is normal and whether the direction of rotation meets the requirements. When do trial running, it should be with 15m/min crawling speed at first, then increse to the highest running speed and finally return to the middle running speed. It should run more than 6h with different working speed, the middle speed running time should not be lower than 4h, high speed running time should be more than 4h.

Operation and maintenance

1) Before production, the inner wall of the roller and the suction seal strip of the vacuum chamber must be running-in during idle running. The running-in method: open the shower pipe inside the roll to make the shell idle running, pass 0.06-0.10Mpa compressed air into rubber tire of sealing strip. When the sealing strip tightly against the inner wall of the roller and running for a certain period of time, check the sealing strip and the inner wall matching condition. The vacuum degree can be only guaranteed on condition that the matching condition is well. It must be injected air in advance when adjusting gate width.

2) Production can only be carried out after normal operation of air, normal supply of slurry, water, electricity and gas, and preparation of cleaning, oiling and inspection of all parts which is necessary before starting up production

3) Check whether the vacuum gauge and pressure gauge are in good condition and whether the pointer is in the zero position.

4) Frequently check the vacuum degree during using. If the vacuum degree is suddenly decreased due to other reasons rather than vacuum system, stop the machine and check the seal strip. The seal strip must be replaced in time after it is worn out.

5) When drawing out the suction box, first turn the vacuum box so that it is perpendicular to the ground in the roller, and then draw out the suction box.

Main points of suction couch roll maintenance

1) maintenance personnel shall clean it frequently to keep the suction roll clean and the roll face and holes be unimpeded

2) Bearing is not only the supporting part in the operation of suction roll, but also an important part in the roll. The staff should check it once a day and clean and change the oil once a year.

3) Check the pressure gauge frequently, see whether the indication is sensitive, pressure change in order to timely find whether there is leakage of air, water leakage phenomenon