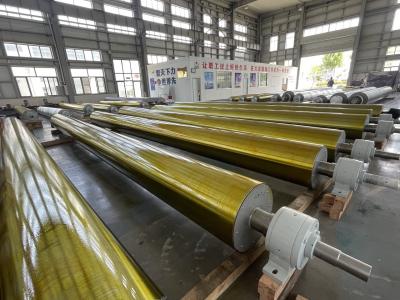

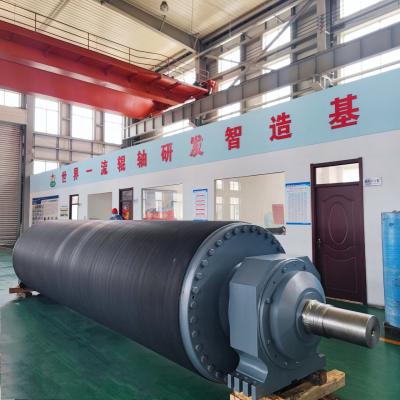

Top Press Roll Of Paper Machine

1:Working speed above 1000m/min;

2:Suitable and Premium Shell and cover material

3:Vibration Diagnostics Sensors for all bearings;

4:Best Chinese Roll Design and Manufacturing;

5:Advanced Storage and Operating &Maintenance Instructions for Rolls;

Top Press roll normally refers to a nip composed of pressing rollers which a diameter from 600mm to 1600mm. It is often used in the production of corrugated paper, cardboard, and other paper or cardboard with large basis weight.

Comparing with original presses type, it has a wide nip formed by the large-spoke press, the paper sheet can be pressed for a long time in the nip. It can improve the dehydration efficiency, increases the de-watering capacity and paper quantity because of the two-way vertical dehydration design.At the same time, it can also reduce steam consumption in the dryer section and further reduces production costs. The strength and burst resistance of the paper also been improved.

Top Press Roll Specification:

Diameter Range: | φ600-1600mm |

Maximum Face Length: | 14000mm |

Shell Material: | Gray Cast Iron; Steel |

Surface type: | Blind Hole, Blind + Through Hole; Smooth or Groove |

Coating: | PU or Rubber |

Journal Material: | Forged 42CrMo; Cast Steel or Nodular Casting Iron |

Bearing housing: | Gray Casting Iron or ZG 35 or Nodular Casting Iron |

Bearing brand: | Chinese brand or SKF or FAG or NSK or Timken |

Connection type: | Flanged Joint |

Our certification :

Our exhibition